Whether you’re building furniture, cabinetry, or decorative pieces, the strength, and durability of your work are essential. Woodworkers often debate whether wood glue is stronger than wood. The answer is; it depends on several factors that may affect the strength of the wood, including the type of wood, wood glue, and other environmental factors.

Although wood glue cannot replace the inherent strength of wood, it can establish a robust bond between two wood pieces.

Nonetheless, wood glue can significantly strengthen and increase the longevity of a joint when applied correctly. It’s a fascinating topic that we’ll explore in-depth in this article.

Contents

Is Wood Glue Stronger than Wood?

Before we dive into the specifics of wood glue, let’s take a moment to understand the basics of woodworking joints. Joints are an essential part of woodworking, as they hold different pieces of wood together to create a single structure.

So, is wood glue stronger than wood? The answer still stands; it depends. While wood glue can create a strong bond between two pieces of wood, it cannot replace the natural strength of the wood itself. However, when used correctly, wood glue can significantly enhance the strength and durability of a joint.

6 Factors That Can Affect the Strength of Wood Glue:

The strength of a wood glue joint can be affected by several factors, including:

1. Type of Glue:

Different types of wood glue have different strengths and properties. For example, polyurethane glue creates a very strong bond, but it can be messy and difficult to work with. PVA glue is easy to use and dries clear, but it may not be as strong as other types of glue.

2. Quality of the Wood:

The quality of the wood being joined can affect the strength of the glue joint. Wood that is too dry or too wet can be more difficult to glue and may not create a strong bond. Wood that is dirty or has a lot of knots or defects can also be more difficult to glue.

3. Preparation of the Surfaces:

Proper preparation of the surfaces to be glued is essential for creating a strong bond. The surfaces should be clean and dry, and any finish or paint should be removed. The surfaces should also fit together tightly and evenly to ensure a strong bond.

4. Clamping Pressure:

Applying the right amount of clamping pressure is essential for creating a strong bond. Too much pressure can force out too much glue and weaken the bond, while too little pressure can prevent the glue from fully penetrating the wood fibers.

5. Drying Time:

Allowing the glue to fully dry is essential for creating a strong bond. If the glue is not given enough time to dry, the bond may be weak and may not hold up over time.

6. Moisture:

Moisture can impact the holding power of both wood glue and nails. Wood glue may not bond as effectively in humid or damp conditions, while nails may be prone to rust or corrosion if exposed to moisture.

It is important to carefully consider these factors when selecting a glue and preparing the surfaces to be joined. Proper technique and attention to detail can help ensure a strong, durable bond.

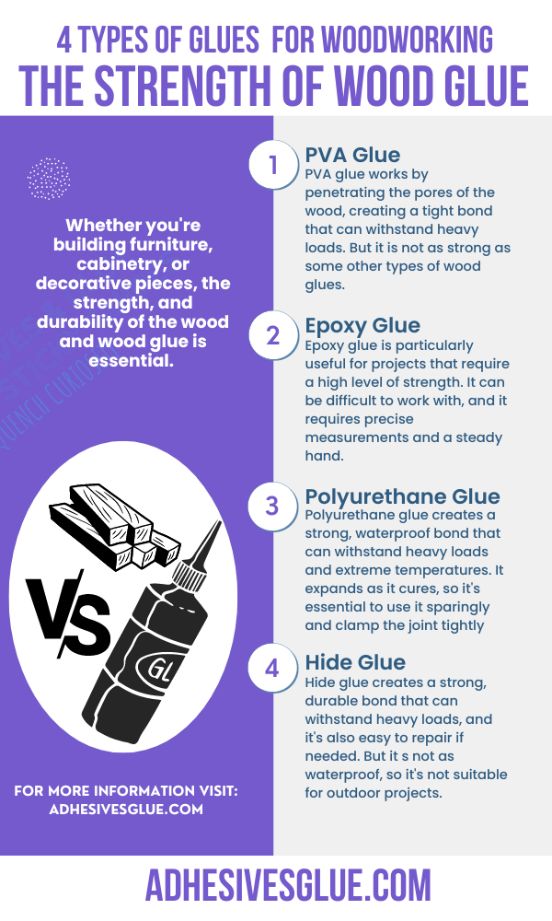

4 Types of Wood Glues and Their Strength

Let’s take a closer look at the different types of wood and their strength.

1. PVA (Polyvinyl Acetate) Glue:

PVA glue is a water-based adhesive that is popular among woodworkers. It’s easy to use and dries clearly, making it an excellent choice for projects that require a seamless finish. PVA glue works by penetrating the pores of the wood, creating a tight bond that can withstand heavy loads.

While PVA glue is not as strong as some other types of wood glue, it’s more than enough for most woodworking projects.

2. Epoxy Glue:

Epoxy glue is a two-part adhesive that consists of a resin and a hardener. When the two components are mixed, they create a strong, durable bond that can withstand heavy loads and extreme temperatures.

Epoxy glue is particularly useful for projects that require a high level of strength, such as boat building or repairing furniture. However, epoxy glue can be difficult to work with, and it requires precise measurements and a steady hand to apply correctly.

3. Polyurethane Glue:

Polyurethane glue is a single-component adhesive that cures through a chemical reaction with moisture in the air. Polyurethane glue creates a strong, waterproof bond that can withstand heavy loads and extreme temperatures.

However, it’s important to note that polyurethane glue expands as it cures, so it’s essential to use it sparingly and clamp the joint tightly to avoid any excess glue from spilling over.

4. Hide Glue:

Hide glue is an ancient adhesive that has been used in woodworking for thousands of years.

It’s made from animal hides and bones and is particularly useful for intricate woodworking projects that require a high level of precision. Hide glue creates a strong, durable bond that can withstand heavy loads, and it’s also easy to repair if needed.

However, hide glue is not as waterproof as some other types of wood glue, so it’s not suitable for outdoor projects.

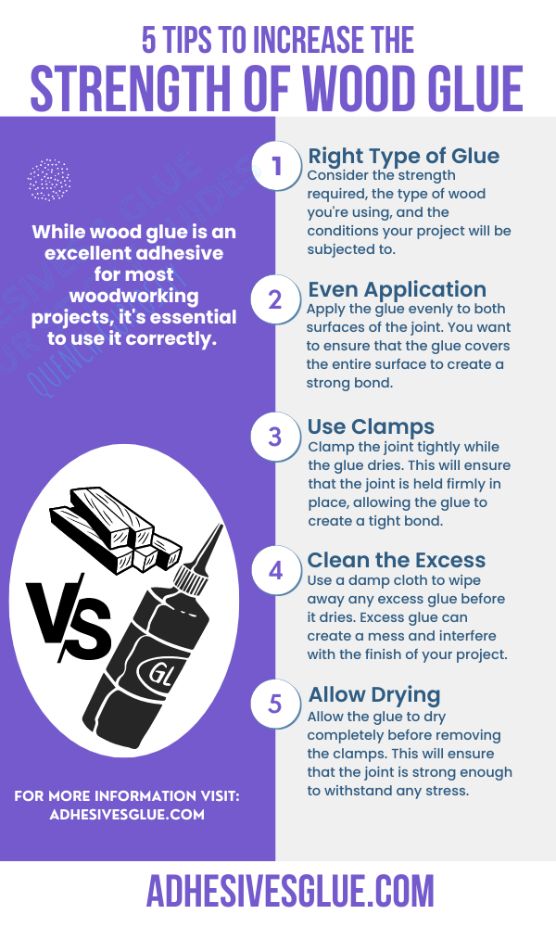

5 Tips to Increase the Strength of Wood Glue:

While wood glue is an excellent adhesive for most woodworking projects, it’s essential to use it correctly. Here are a few tips for using wood glue to create stronger joints:

1. Right Type of Glue:

Choose the right type of glue for your project. Consider the strength required, the type of wood you’re using, and the conditions your project will be subjected to.

2. Even Application:

Apply the glue evenly to both surfaces of the joint. You want to ensure that the glue covers the entire surface to create a strong bond.

3. Use Clamps:

Clamp the joint tightly while the glue dries. This will ensure that the joint is held firmly in place, allowing the glue to create a tight bond.

4. Clean the Excess:

Use a damp cloth to wipe away any excess glue before it dries. Excess glue can create a mess and interfere with the finish of your project.

5. Allow Drying:

Allow the glue to dry completely before removing the clamps. This will ensure that the joint is strong enough to withstand any stress.

By understanding the different types of wood glue and how they work, you can choose the right adhesive for your project and create joints that will stand the test of time. Remember to use wood glue correctly, and you’ll be on your way to creating beautiful and robust woodworking projects.

Conclusion:

In conclusion, woodworking projects often rely on the strength and durability of joints between two or more pieces of wood. While the strength of wood glue is natural, it can be improved by paying attention to the tips mentioned above.

Wood glue works by creating a chemical bond between the wood pieces, which can significantly increase the overall strength of the joint. Though wood glue cannot replace the natural strength of wood, it can provide an additional layer of reinforcement when used correctly.

By selecting the right type of glue for the project, applying it evenly, and allowing it to fully cure, woodworkers can create strong and durable joints that stand the test of time. So next time you’re working on a woodworking project, don’t forget the power of wood glue in creating long-lasting and sturdy joints.

I fell in love with crafts & fixing things when I was 11 years old – after discovering the world of blogging, I am combining my passions to present the world with well-researched guides & reviews about everything related to adhesives & glue.