Are you looking for an answer to the question of how to glue rubber to aluminum? If so, you’ve come to the right place. In this blog post, we’ll go over some of the methods used when it comes to bonding rubbery and metallic materials.

And by using our helpful tips and tricks, you can rest assured that your project will be successful! So whether you are working on a small DIY project or a large industrial task – let us help make your job easier!

Contents

- 1 How to Glue Rubber to Aluminum? 6 Easy Steps

- 2 Types of Glues to Bond Rubber to Aluminum

- 3 List of Best Glues to Bond Rubber to Aluminum

- 4 Health Hazard of Bonding Rubber to Aluminum

- 5 Safety Precautions When Bonding Rubber to Aluminum

- 6 FAQS

- 7 1. Can rubber withstand high temperatures?

- 8 2. Are there any special tips to keep in mind when gluing rubber to aluminum?

- 9 3. How long should I wait for the glue to dry when gluing rubber to aluminum?

- 10 4. How should I prepare the surfaces to glue rubber to aluminum?

- 11 5. What should I do if the glue does not stick to the rubber or aluminum?

- 12 Conclusion

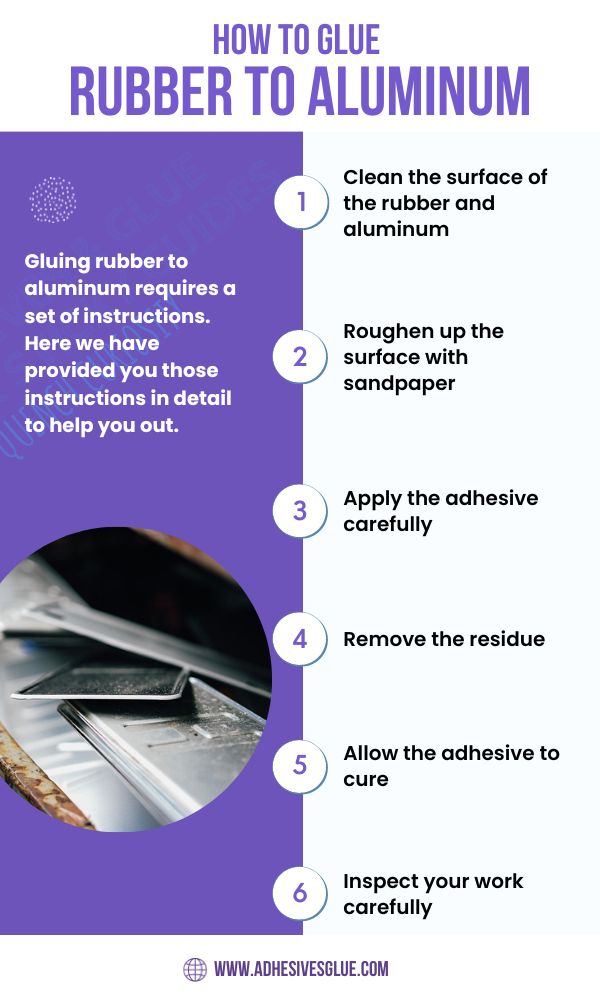

How to Glue Rubber to Aluminum? 6 Easy Steps

Gluing rubber to aluminum is a common task that can be achieved with the right adhesive and steps. Fortunately, this isn’t an overly complicated process and we’re here to guide you through it! Here are six simple steps for gluing rubber to aluminum:

1. Clean the Surfaces

Start by cleaning both surfaces using an acetone-based cleaner or soap and water and scrub both surfaces gently until all dirt and debris are removed. You can scrub the surfaces by using a soft cloth or a soft brush with cleaner applied to it.

Make sure any dirt, dust, grease, oil, or other contaminants have been removed from the surface of the aluminum and rubber before continuing. This will help ensure the adhesive bonds effectively on contact.

2. Roughen Up the Surfaces

Next, use sandpaper to roughen up the surface of the rubber and aluminum pieces. You want them to have enough texture for the adhesive to cling onto, so make sure each area has tiny ridges and valleys.

3. Apply the Adhesive

Once you’ve prepped the surface areas, it’s time to apply the glue. Prepare your adhesive according to the manufacturer’s instructions on its packaging. Apply it carefully to one surface only – either aluminum or rubber – but not both.

4. Allow Adhesive to Cure

When you have applied the adhesive, press the two pieces together gently but firmly until they have bonded completely. Allow them to sit undisturbed before testing their bond strength. The amount of time it takes will depend on the type of adhesive used, so be sure to check its instructions for curing time.

5. Remove the Residue

After the curing process is complete, remove any excess glue with a damp cloth or soft brush. Do not use anything abrasive on either surface as this could damage it!

6. Inspect Your Work

Finally, inspect your work to make sure that there are no gaps or weak spots in the bond. If everything looks good, then you’re finished! You’ve completed gluing rubber to aluminum – congratulations!

These steps will help ensure a strong and durable bond between the two surfaces that should last for years to come. With careful preparation and attention to detail, you can easily glue rubber to aluminum with confidence.

Explore More:

- Hot Glue Without a Gun: 5 Amazing Methods to Use Hot Glue

- Hot Glue on Metal: 5 Metals That Definitely Work With Hot Glue

Types of Glues to Bond Rubber to Aluminum

Gluing rubber to aluminum can be a tricky task, but it doesn’t have to be. Depending on your project there are several types of glues you can use to bond rubber to aluminum. Here’s a list of the best glues for any project:

1. Silicone Adhesive

An ideal choice for adhering rubber to aluminum, silicone adhesive offers superior flexibility and strength when bonding dissimilar materials. It’s also water-resistant and works well in extreme temperatures.

2. Cyanoacrylate Adhesive

Also known as “super glue,” cyanoacrylate is an excellent option for bonding rubber to aluminum due to its fast drying time and stronghold after curing.

3. Epoxy

If you’re looking for a strong, temperature-resistant bond, opt for epoxy. It takes longer to dry and is more difficult to work with than the other glues on this list, but it will provide the strongest bond.

4. Neoprene Contact Adhesive

This glue has both adhesive and cohesive properties, making it highly versatile when bonding rubber to aluminum. It also dries quickly and can withstand temperature variations without losing its stickiness.

5. Urethane Adhesive

This type of adhesive provides excellent adhesion between dissimilar materials like rubber and aluminum while being flexible enough to expand or contract along with the materials as needed.

No matter which type of glue you choose, make sure to read and follow the instructions carefully for the best results. With a little bit of preparation, your rubber-to-aluminum project should be a breeze!

Explore More

- Is Gorilla Glue Waterproof? Tips And Hacks To Use It Effectively

- Best Glue For Polycarbonate – 8 Amazing Options For You

List of Best Glues to Bond Rubber to Aluminum

When it comes to gluing rubber to aluminum, there are several options available. Here is a list of some of the most popular brands of glue for bonding rubber and aluminum:

- 3M Super 77 Multipurpose Spray Adhesive

- E6000 Craft Adhesive

- Loctite Plastics Bonding System

- JB Weld Original Cold-Weld Formula

1. 3M Super 77 Multipurpose Spray Adhesive

3M Super 77 Multipurpose Spray Adhesive is the perfect product for your needs. It forms a strong bond with metal, plastic, wood, and fabric.

Key Features

- Quick curing time

- Strong bond

- Clean appearance

2. E6000 Craft Adhesive

E600 Craft Adhesive is an industrial adhesive. It offers flexibility and superior strength. Moreover, it is versatile in its use as it can be used on multiple surfaces such as metal, rubber, plastics, vinyl, wood, and leather.

Key Features

- Paintable

- UV resistant

- Waterproof

- Low odor

3. Loctite Plastics Bonding System

This system is designed specifically for bonding dissimilar materials like plastic, rubber, and metal. Its unique formula creates a strong bond that won’t yellow or crack over time.

Key Features

- Water-resistant

- Chemical resistant

- Weather resistant

- Fast drying time

4. JB Weld Original Cold-Weld Formula

JB Weld Original Cold-Weld Formula can help you glue rubber to aluminum quickly and easily. Its two-part epoxy is designed to create a strong bond in even the most demanding applications. It forms a permanent and strong bond.

Key Features

- High weather resistance

- Can be shaped, filed, tapped, needed, drilled, sanded, and molded after curing

Health Hazard of Bonding Rubber to Aluminum

When it comes to gluing rubber to aluminum, there are potential health hazards involved. Rubber contains certain organic compounds and chemicals which can react with the aluminum to form toxic gases such as:

- Carbon dioxide

- Nitrogen oxides

- Sulfur dioxide

These gases can be hazardous when inhaled for extended periods. Additionally, fumes from burning rubber combined with aluminum can irritate the eyes, throat, and lungs. Therefore, it is important to take safety precautions when bonding rubber to aluminum.

Safety Precautions When Bonding Rubber to Aluminum

Safe gluing and minimizing the risk of releasing any hazardous substances can be ensured by following proper precautionary measures.

- Wear goggles, gloves, and respirators

- Work in well-ventilated areas

- Dispose of excess material formed during the bonding process

FAQS

1. Can rubber withstand high temperatures?

Natural rubber must not be used in an application with a temperature above 80 degrees Celsius. However, some synthetic rubbers have been engineered can tolerate temperatures up to 300 degrees Celsius.

2. Are there any special tips to keep in mind when gluing rubber to aluminum?

First, make sure to apply the epoxy glue evenly and in a thin layer. Too much glue can cause air bubbles that weaken the bond, while too little glue will not create a strong bond.

Also, it is important to wear protective gloves and eye gear while applying the glue. Finally, follow the instructions on the package closely for the best results.

3. How long should I wait for the glue to dry when gluing rubber to aluminum?

The amount of time it takes for epoxy glue to dry can vary depending on the temperature and humidity in the area. Generally, it takes 24-48 hours for epoxy glue to completely dry and cure.

For best results, allow the glue to dry for 24-48 hours before using the rubber and aluminum object.

4. How should I prepare the surfaces to glue rubber to aluminum?

Before gluing rubber to aluminum, it is important to make sure that both surfaces are clean of dirt, oil, and moisture. Use a lint-free cloth to wipe down the aluminum surface, and use mild soap and warm water to clean the rubber surface. Once both surfaces are dry, you can apply the epoxy glue.

5. What should I do if the glue does not stick to the rubber or aluminum?

If the glue does not seem to be sticking, it could mean that one or both of the surfaces were not properly prepped before gluing. Clean both the rubber and aluminum surfaces again, then allow them to dry completely. Then, apply a thin, even layer of epoxy glue and allow it to dry before using the object.

If the surfaces have been previously sealed, sand or etch them first for better adhesion.

Conclusion

There you have it, an easy guide on how to glue rubber to aluminum. No matter the project you’re undertaking, it’s important to have a reliable bond, and choosing the right adhesive is an important part of this process.

Take the necessary safety precautions when using adhesives, read directions carefully, and only use products that are suitable for the materials involved. Best of luck with your projects!